SUPERBOT-5 32-Socket Fully Automated IC Programmer

Part No.: MPXT-SUPERBOT-5-32-Socket-Fully-Automated-IC-Programmer

32-Socket Automated IC Programmer with Quad Nozzles

產品介紹

32-Socket Automated IC Programmer with Quad Nozzles

"24/7 Superior Automated Programming Workhorse"

Xeltek SuperBOT5 fully automated IC programmer offers high performance at a reasonable price. The automated system is suitable for all productions with high to low programming output. Equipped with quad nozzles for pick & place action with two CCD cameras and accepts dual tape feeders. SBOT5 is embedded with our superior SUPERPRO 7500, offering ultra-high-speed programming and up to 2500UPH. Up to 32-sockets with 8 independent socket pressing actuators. Built-In industrial Windows XP PC, with a 19” display, Mouse & Keyboard.

SUPERBOT5 compatible for high density chips such has eMMC & NAND flash.

Varied I/O devices

.png) |

Standard Manual Tray:

Standard I/O device of the machine. Operator will replace the programmed tray from |

|

|---|---|---|

.png) |

Auto Tray Device

This device is an extension of the fixed tray. It includes tray-in and tray-out and users |

|

.png) |

Tape-In Device

Electric Tape in feeder. Tape width between 8 and 32mm applicable. Tape-in device |

|

.png) |

Tape-Out Device

Connects to a SuperBOT 5 or SuperBOT3 for fully automatic operation. 8-32 mm tape |

|

.png) |

Tube-In

Moves chips in the machine. Chip guider for different chip width (optional). IO is multi |

|

.png) |

Tube-Out

Moves chips out of the machine. Chip guider for different chip width (optional). IO is |

|

.png) |

Laser Marker System

An optional attachment to the tape-out or the auto tray device for high speed marking. |

|

.png) |

Tape Ink-Marker

Add-on item for tape out machine. On completion of programming the chip can be Tray Ink Marker

Add-on item for auto tray machine. On completion of the programming the chip can be |

|

Advantages of SuperBOT-5

.png) |

High Programming Output:

Achieve up to 2,500 Units Per Hour (for devices with programming time less than 50

SBOT5 offers 8 programming channels which can supports up to 4Gang socket

The automated system can be operated 24 hours 7 days offering an output of |

|

|---|---|---|

.png) |

Superior Performance:

Powered by 8 ultra-high speed SUPERPRO 7500 universal gang programmer. |

|

.png) |

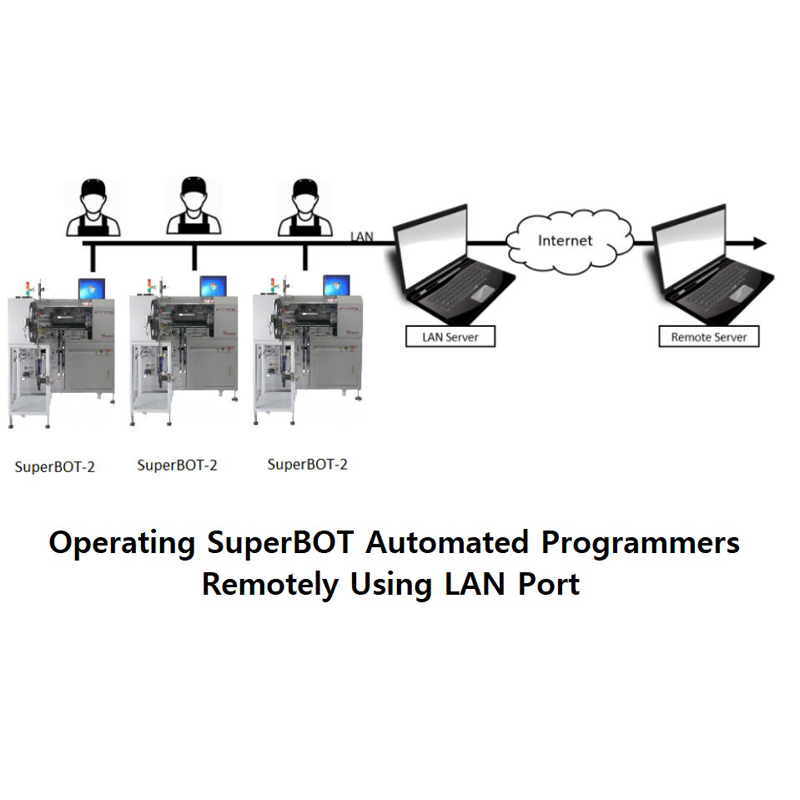

LAN Operation:

Most volume programming applications need programmers to be operated remotely |

|

|

|

The Most Durable and Reliable Systems in the Industry

China is the hub of the world Electronics manufacturing and Xeltek automated |

|

.png) |

Largest Device Support

Located in Silicon Valley, we keep good relationships with many major IC companies |

|

.png) |

Better Yield:

Our semiconductor manufacturer approved algorithms, precision and clean signals |

|

.png) |

Supports most types of packages & sizes

Xeltek has supported many package types with a varieties of chip sizes. Today we |

|

.png) |

Powerful and Intelligent Software:

Built-in Industrial PC with Windows XP, 19” LCD Display, Keyboard & Mouse. Project |

|

.png) |

Powerful and Intelligent Software:

Built-in Industrial PC with Windows XP, 19” LCD Display, Keyboard & Mouse. Project |

|

.png) |

Short change-over time

Xeltek SuperBOT accessories can be easily changed when programming task |

|

.png) |

Socket Cost and Investment:

Cost recovery in short period with low investment in the beginning as socket adapters |

|

.png) |

Technical Support:

More than 30 engineers are devoted to developing new programmers, socket adapters |

|

Xeltek offers free training up to 5 days at our factory. Why we offer free training?

When it comes to production programming time cannot be wasted, while waiting for a certified technician like most companies offer it may take several days until they can service your unit losing production time. With our training classes we will show you how to service, operate and troubleshoot the Automated System, leading to low cost maintenance service and quick repair done by your operators. Our free training has be beneficial to all our SuperBot customers, leaving them confident about our SuperBot. Confident enough that our customer AITEK a Mom & Pop shop was able to tame their SuperBot 3 with little to no help. They were able to set up their unit within 1 day!

What is included?

|

SuperBOT5 equipped with: |

Optional Accessories |

|

|---|---|---|

|

|

|

Motion System

|

Motion System |

High Performance Control Card & Servo Drive System. |

|

|---|---|---|

|

Resolution |

X axis: ±0.02mm; Y axis: ±0.02mm; Z axis: ±0.02mm; θaxis: ±0.1° |

|

|

Stroke |

X axis: 1000mm; Y axis: 500mm; Z axis: 40mm |

|

|

Pick & Place |

±0.07mm |

|

|

Operable Chip |

Minimum: 2x2mm; Maximoum: 25x25mm |

|

|

Maximum |

2500 Units Per Hour |

|

Vision System

|

Camera |

Dual CCD Card; Upward CCD for IC positioning while the |

|

|---|---|---|

|

Field of View |

30x30mm |

|

|

Vision Accuracy |

△x=△y=0.07 mm, △θ=0.1° |

|

Electrical & Hardware Specifications

|

Devices Supported |

EPROM, Paged EPROM, Parallel and Serial EEPROM, FPGA Configuration PROM, |

||

|---|---|---|---|

|

Package |

DIP, SDIP, PLCC, JLCC, SOIC, QFP, TQFP, PQFP, VQFP, TSOP, SOP, TSOPII, PSOP, |

||

|

Power Supply |

AAC 200~240V/50~60Hz, single phase |

||

|

Power Consumption |

1.5KVA |

||

|

Air |

Clean, pressure: 0.6MPa, consumption: 50 liter/min |

||

|

Size |

Main Machine |

1280 (L) x 840 (W) x 1500 (H) |

|

|

Auto Tray |

1100(L)×380(W)×1300(H) mm |

||

|

Tape-Out |

1100(L)×380(W)×1300(H) |

||

|

Weight |

Main machine: 450 Kg Auto tray: 80 Kg Tape out: 80 Kg |

||

|

Shipping Dimension |

Main Machine |

1280(L) X 840 (W) x 1500 (H) mm |

|

|

Auto Tray |

1100(L)×380(W)×1300(H) mm |

||

|

Tape-Out |

1100(L)×380(W)×1300(H) mm |

||

|

Shipping Weight |

Main machine: 450 Kg Auto tray: 80 Kg Tape out: 80 Kg |

||

.png)