Modular Engine Management "Motronic ME 1.0.2"

Part No.: MPLCNL-Modular-Engine-Management-Motronic-ME-1.0.2

The safety measurement sockets and the "all-in-one" measuring apparatus offer students multiple options for carrying out measurements on the training system.

產品介紹

Modular Engine Management "Motronic ME 1.0.2"

This engine management system provides trainees with all the necessary components (engine control unit, sensors, actuators, power supply) for modular assembly and configuration. This means that the complexity of the system can be adapted to need and an in-depth understanding can be gained of communication between individual sensors or actuators and the engine control unit, considering input, processing and output as a basic principle.

To ensure the perfect symbiosis between theory and practice, all the modules have genuine, fully functioning components wherever possible. These are then complemented with realistic drawings. To further enhance the practical aspect and make it true to life, each module has a simulation mode and an authentic mode, such that it is possible to measure the actual air-flow by mass using the authentic flow meter. In addition, the response of the entire system can be analysed when plugs and connecting leads are removed. The on-board diagnostic (OBD) connector on the control unit allows previously activated simulated faults to be read out.

The safety measurement sockets and the "all-in-one" measuring apparatus offer students multiple options for carrying out measurements on the training system. The accompanying course software provides not only the extensive interactive and theoretical content but also the necessary virtual instruments to convert your own Windows device into a powerful, multi-functional measurement platform (voltmeters, oscilloscope) with the simultaneous capability to document the results of measurements

To meet the requirements for such training systems, the individual modules are provided with short-circuit protection so that they have the suitable resilience to faulty operation.

Basic Equipment Set, Consisting of...

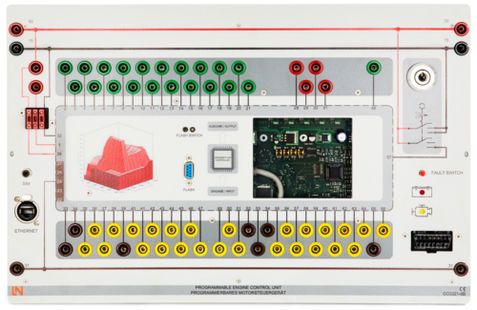

Programmable Engine Control Unit

The core of the "Modular engine management system" is the engine control unit which can be programmed as needed. It has its own modifications for educational purposes which are perfect for showing how the controller receives input, processes it and outputs the appropriate signals. All the control unit's pins are connected to sockets on the neatly laid out front panel so that measurements can be made on them directly. Thanks to the colour-coding of the 4-mm safety sockets, it is easy to identify the actual function of each of the pins (sensors, actuators, power, ground) at a glance. The control unit also proves to be multi-talented in the area of diagnostics. It is possible to use the fault switches or the OBD socket to read out standard P0 codes but also to monitor real-time data and modifications with the help of the Ethernet port and matching software. This enables you to cover the telecommunications topics of how Ethernet and IP are used in vehicles

Technical highlights:

- Changing sets of parameters via Ethernet link

- Software status can be written to flash memory via RS 232 port

- Measurement and configuration software can also be connected via Ethernet

- On-board diagnostics via OBD port, malfunction indicator light (MIL) and fault simulation switches

- Indicator light for detection of rpm signal

- Indicator light for detection of switch enabling flash memory writes

- Status display for ignition voltage

- Ignition/start switch

- 26 inputs for various sensors with 4-mm safety measurement sockets

- 21 power outputs for various actuators with 4-mm safety measurement sockets

- Digital sensor ground terminals connected to 4-mm safety measurement sockets

- Analog sensor ground terminals connected to 4-mm safety measurement sockets

- Central power and ground rails in DIN colours

- Fuses: 3 x 15 A

- 1 cinch output for additional simulation signals

- Inputs and outputs: 4-mm safety sockets

Technical details:

- Operating voltage: 12 V

- Dimensions: 297 x 445 x 180 mm (HxWxD)

- Weight: 3.4 kg

Injection Valves (Manifold Fuel Injection)

.jpg)

The modular unit “Injection valves” is part of the "Modular Engine Management" training system. Thanks to the symbiosis of real components with digitally generated graphics it is possible to fully exploit the maximum possible knowledge transfer of the individual module. The trainee gets to know, on the one hand, how the component really looks and how the part feels to the touch but can also link the physical appearance directly to the corresponding circuit symbol which is critical in helping individuals read and understand circuit diagrams. Depending on the module there are besides circuit symbols also 3D illustrations which depict the respective component in detail. Since the 4-mm safety sockets of the module have the same colour coding as the control unit, the basic function of the respective connections is not only self-explanatory but also minimises the danger of making faulty wiring connections. In the event a mistake is made in the wiring, the sensor and actuator modules are equipped with built-in safety circuitry which protects against short-circuits.

Technical highlights:

- Four real fuel injection valves (manifold fuel injection)

- Circuit symbol with measurement points

- Short-circuit proof

Technical details:

- Operating voltage: 12 V

- Dimensions: 297 x 227 x 180 mm (HxWxD)

- Weight: 1.3 kg

Tank Purge Valve

The modular unit "Tank purge valve" is part of the "Modular Engine Management" training system. Thanks to the symbiosis of real components with digitally generated graphics it is possible to fully exploit the maximum possible knowledge transfer of the individual module. The trainee gets to know, on the one hand, how the component really looks and how the part feels to the touch but can also link the physical appearance directly to the corresponding circuit symbol which is critical in helping individuals read and understand circuit diagrams. Depending on the module there are besides circuit symbols also 3D illustrations which depict the respective component in detail. Since the 4-mm safety sockets of the module have the same colour coding as the control unit, the basic function of the respective connections is not only self-explanatory but also minimises the danger of making faulty wiring connections. In the event a mistake is made in the wiring, the sensor and actuator modules are equipped with built-in safety circuitry which protects against short-circuits.

Technical highlights:

- Real tank purge valve

- Circuit symbol with measurement points

- Short-circuit proof

Technical details:

- Operating voltage: 12V

- Dimensions: 297 x 227 x 180mm (HxWxD)

- Weight: 1.3kg

Knock Sensor

.jpg)

The modular unit "Knock sensor" is a component of the "Modular Engine Management" training system. Thanks to the symbiosis of real components with digitally generated graphics it is possible to fully exploit the maximum possible knowledge transfer of the individual module. The trainee gets to know, on the one hand, how the component really looks and how the part feels to the touch but can also link the physical appearance directly to the corresponding circuit symbol which is critical in helping individuals read and understand circuit diagrams. Depending on the module there are besides circuit symbols also 3D illustrations which depict the respective component in detail. Since the 4-mm safety sockets of the module have the same colour coding as the control unit, the basic function of the respective connections is not only self-explanatory but also minimises the danger of making faulty wiring connections. In the event a mistake is made in the wiring, the sensor and actuator modules are equipped with built-in safety circuitry which protects against short-circuits.

Technical highlights:

- Real knock sensor

- Circuit symbol with measurement points

- Switch for real and simulation operating modes

- Simulation of normal combustion and combustion subject to knocking

- Short-circuit proof

Technical details:

- Operating voltage: 5V

- Dimensions: 297 x 116 x 180 mm (HxWxD)

- Weight: 0.8 kg

Fuel Pump

.jpg)

The "Fuel pump" module is part of the “Modular engine management” training system. Its symbiosis between authentic components and digitally rendered graphics means you can get the full educational potential out of the module. Trainees not only learn the authentic look and feel of the components but can also associate this actual appearance with the corresponding circuit symbol, which is a major help in reading and understanding circuit diagrams. Depending on the actual module, there may also be a 3D drawing as well as the circuit symbol, which shows details of the component. Since the 4-mm safety sockets used for the module use the same colour-coding as the control unit, not only is the basic function of each terminal self-explanatory but also the dangers of incorrect wiring are minimised. Even if wiring is done incorrectly, all the sensors and actuator modules possess inherent safety circuitry to protect them against short-circuits.

Technical highlights:

- Authentic fuel pump

- Short-circuit-proof

- Circuit symbol with measuring points

Technical details:

- Operating voltage: 12 V

- Dimensions: 297 x 116 x 180 mm (HxWxD)

- Weight: 0.8 kg

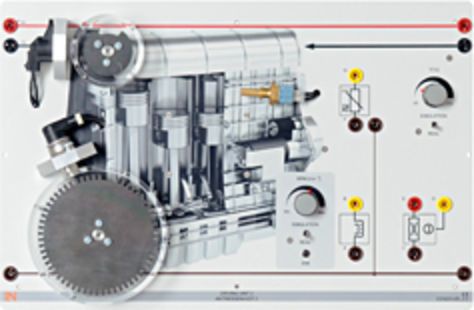

Drive Unit with Crankshaft, Camshaft and Engine Temperature Sensor

The "Drive unit 2" module is part of the “Modular engine management” training system. Its symbiosis between authentic components and digitally rendered graphics means you can get the full educational potential out of the module. Trainees not only learn the authentic look and feel of the components but can also associate this actual appearance with the corresponding circuit symbol, which is a major help in reading and understanding circuit diagrams. Depending on the actual module, there may also be a 3D drawing as well as the circuit symbol, which shows details of the component. Since the 4-mm safety sockets used for the module use the same colour-coding as the control unit, not only is the basic function of each terminal self-explanatory but also the dangers of incorrect wiring are minimised. Even if wiring is done incorrectly, all the sensors and actuator modules possess inherent safety circuitry to protect them against short-circuits.

Technical highlights:

- Authentic crankshaft sensor

- Authentic camshaft sensor

- Authentic engine temperature sensor

- Short-circuit-proof

- Circuit symbol with measuring points

- Switch for selecting between actual and simulated engine temperature modes

- Continuous simulation of temperature changes in a range from -20 to 110°C.

- Switch for selecting between actual and simulated crankshaft and camshaft modes

- Continuous simulation of speed or actual control by accelerator pedal sensor.

- High-resolution printed cut-away of R4 engine

Technical details:

- Operating voltage: 5 V

- Dimensions: 297 x 445 x 180 mm (HxWxD)

- Weight: 3.4 kg

Lambda Sensor (Electrically Heated)

.jpg)

The modular unit "Lambda sensor (electrically heated)" is part of the "Modular Engine Management" training system. Thanks to the symbiosis of real components with digitally generated graphics it is possible to fully exploit the maximum possible knowledge transfer of the individual module. The trainee gets to know, on the one hand, how the component really looks and how the part feels to the touch but can also link the physical appearance directly to the corresponding circuit symbol which is critical in helping individuals read and understand circuit diagrams. Depending on the module there are besides circuit symbols also 3D illustrations which depict the respective component in detail. Since the 4-mm safety sockets of the module have the same colour coding as the control unit, the basic function of the respective connections is not only self-explanatory but also minimises the danger of making faulty wiring connections. In the event a mistake is made in the wiring, the sensor and actuator modules are equipped with built-in safety circuitry which protects against short-circuits.

Technical highlights:

- Real lambda sensor

- Circuit symbol with measurement points

- Switch for real and simulated operation

- Continuous simulation of a aged and a new unit

- Short-circuit proof

Technical details:

- Operating voltage: 12V, 5V

- Dimensions: 297 x 116 x 180mm (HxWxD)

- Weight: 0.8 kg

Mass Air Flow Sensor

.jpg)

The "Mass air flow sensor" module is part of the “Modular engine management” training system. Its symbiosis between authentic components and digitally rendered graphics means you can get the full educational potential out of the module. Trainees not only learn the authentic look and feel of the components but can also associate this actual appearance with the corresponding circuit symbol, which is a major help in reading and understanding circuit diagrams. Depending on the actual module, there may also be a 3D drawing as well as the circuit symbol, which shows details of the component. Since the 4-mm safety sockets used for the module use the same colour-coding as the control unit, not only is the basic function of each terminal self-explanatory but also the dangers of incorrect wiring are minimised. Even if wiring is done incorrectly, all the sensors and actuator modules possess inherent safety circuitry to protect them against short-circuits.

Technical highlights:

- Authentic hot-film mass air flow sensor

- Circuit symbol with measuring points

- Short-circuit-proof

- Built-in function for measuring intake air temperature

- Switch for selecting between actual and simulated intake air temperature modes

- Continuous simulation of temperature changes in a range from -20 to 110°C.

- Switch for selecting between actual and simulated air flow modes

- Continuous simulation of mass air flow

Technical details:

- Operating voltage: 12 V, 5 V

- Dimensions: 297 x 227 x 180 mm (HxWxD)

- Weight: 1.3 kg

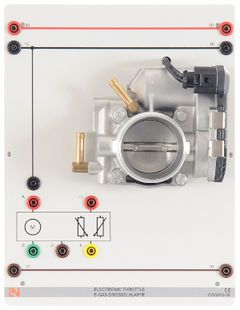

E-Gas Throttle Valve

The "E-Gas throttle valve" module is part of the “Modular engine management” training system. Its symbiosis between authentic components and digitally rendered graphics means you can get the full educational potential out of the module. Trainees not only learn the authentic look and feel of the components but can also associate this actual appearance with the corresponding circuit symbol, which is a major help in reading and understanding circuit diagrams. Depending on the actual module, there may also be a 3D drawing as well as the circuit symbol, which shows details of the component. Since the 4-mm safety sockets used for the module use the same colour-coding as the control unit, not only is the basic function of each terminal self-explanatory but also the dangers of incorrect wiring are minimised. Even if wiring is done incorrectly, all the sensors and actuator modules possess inherent safety circuitry to protect them against short-circuits.

Technical highlights:

- Real throttle valve with position sensor and actuator

- Circuit symbol with measurement points

- Short-circuit proof

- Switches for real and simulation mode of the throttle valve opening angle

- Continuous simulation of the throttle valve opening angle

Technical details:

- Operating voltage: 5V, 12V

- Dimensions: 297 x 227 x 180mm (HxWxD)

- Weight: 1.3kg

Throttle Pedal Position Sensor

The "Throttle position sensor" module is part of the “Modular engine management” training system. Its symbiosis between authentic components and digitally rendered graphics means you can get the full educational potential out of the module. Trainees not only learn the authentic look and feel of the components but can also associate this actual appearance with the corresponding circuit symbol, which is a major help in reading and understanding circuit diagrams. Depending on the actual module, there may also be a 3D drawing as well as the circuit symbol, which shows details of the component. Since the 4-mm safety sockets used for the module use the same colour-coding as the control unit, not only is the basic function of each terminal self-explanatory but also the dangers of incorrect wiring are minimised. Even if wiring is done incorrectly, all the sensors and actuator modules possess inherent safety circuitry to protect them against short-circuits.

Technical highlights:

- Authentic throttle (accelerator pedal) position sensor with kick-down function

- Short-circuit-proof

- Circuit symbol with measuring points

- Switch for selecting between actual and simulated modes

- Continuous simulation of pedal position

Technical details:

- Operating voltage: 12 V

- Dimensions: 297 x 116 x 180 mm (HxWxD)

- Weight: 0.8 kg

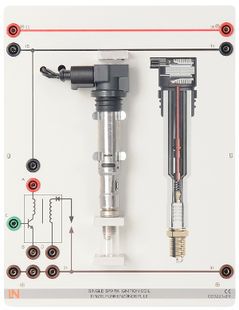

Single Spark Ignition Coil

The modular unit "Single spark ignition coil" is a component of the "Modular Engine Management" training system. Thanks to the symbiosis of real components with digitally generated graphics it is possible to fully exploit the maximum possible knowledge transfer of the individual module. The trainee gets to know, on the one hand, how the component really looks and how the part feels to the touch but can also link the physical appearance directly to the corresponding circuit symbol which is critical in helping individuals read and understand circuit diagrams. Depending on the module there are besides circuit symbols also 3D illustrations which depict the respective component in detail. Since the 4-mm safety sockets of the module have the same colour coding as the control unit, the basic function of the respective connections is not only self-explanatory but also minimises the danger of making faulty wiring connections. In the event a mistake is made in the wiring, the sensor and actuator modules are equipped with built-in safety circuitry which protects against short-circuits.

Technical highlights:

- Real compact ignition coil including spark plugs

- Generates a real ignition spark

- Circuit symbol with measurement points

- Short-circuit proof

Technical details:

- Operating voltage: 12V

- Dimensions: 297 x 227 x 180mm (HxWxD)

- Weight: 1.3kg

Power Supply

Power Supply, 13.5 V, 45 A

.jpg)

The "Power supply" module is part of ´various training systems including the "Modular engine management" system. It provides power to various components in a similar to the way they are supplied in practice in a real engine by means of a 12 V battery. The module employs a 600 watt power unit which can supply a maximum current of 45 A at 13.5 V between its screw terminals. To protect the training system, a maximum current of 30 A can be tapped via the 4-mm safety sockets. This protective function is implemented by electronic monitoring of the 4mm safety sockets. Thanks to the high-resolution printing on the front panel, the module can immediately be identified as a typical car battery.

Technical highlights:

- Stable on-board network voltage of 13.5 volts

- Automatic cut-out without fuses

- Short-circuit protection

- Typical appearance of a vehicle battery thanks to high-resolution printed image of a starter battery

- Maximum current: 45 A

Technical details:

- Operating voltage: 90-264 V AC (47-63 Hz)

- Dimensions: 297 x 227 x 180 mm (HxWxD)

- Weight: 1.6 kg

Measuring Instruments

Modular Measurement Interface

The CarTrain Interface takes the form of a DIN A4 experiment card with rounded corners, colour-coded in compliance with DIN72551 for educational assistance.

Safety measurement sockets are also coded on the basis of DIN72551.

The design resembles circuit diagrams depicted in a detached or exploded view with power supply wiring running between panels.

- Interface for multimedia experiment literature – measurements need to be copied into the experiment instruction pages using drag and drop.

- Two voltage values and one current can all be measured simultaneously

- 3-channel oscilloscope function can be used at the same time as the multimeter display

- Measurement range: V<250 V=/~, I<15A=/~ direct measurement within the circuit

- USB interface

- External power supply to ensure measurements can be made even when short circuits are present

- Current measuring range protected by automatic circuit breaker

- Dimensions: 228 x 296 x 125 mm (WxHxD)

- Weight: 2 kg

Media

Interactive Lab Assistant: Motronic ME 1.0.2 (Modular)

.jpg)

The "Motronic ME 1.0.2" ILA course in conjunction with the "Modular engine management: Motronic ME 1.0.2" training system together represent the perfect symbiosis of theory and practice. Their cogent and logical design immediately encourages the natural interest of trainees and enables them to understand the complexity of engine management systems without difficulty. This is aided by numerous animations for which an entire common rail engine was digitally rendered. It gives students the opportunity to discover the purpose and working principles of sensors and actuators from a completely new perspective.

Working with the hardware and how to carry out the many experiments are also explained in the course using interactive methods. This strictly minimises the time needed to prepare experiments, in particular because all the measuring instruments (e.g. oscilloscope and voltmeters) are already integrated into the course. This gives students more time to concentrate on the key aspects and perceptibly improves their own efficiency. Thanks to the careful selection of theoretical content, all the key aspects of theory which are essential to understanding and to diagnostic expertise are covered.

To round off the package as a whole, the course also provides tests specific to each section of the course structure and determines the knowledge possessed by each individual student. This gives teachers, and the students themselves, constant feedback on the current progress.

Additionally Recommended

Protection Cover for Three-Level Experiment Trolleys

Dust cover for three-level experiment trolleys

- For protecting equipment from dust and damp

- For keeping equipment out of sight (the cover must not be transparent, so is therefore opaque)

- Colour: matt dark grey with printed LN logo in orange)

- Material: nylon fabric with polyurethane coating

- High resistant to tearing, impregnated to be washable and waterproof

Accessories

Mobile Aluminum Experiment Stand, 3 Levels, Power Strip with 6 Sockets, 49"x28"x79" WxDxH (1250x700x1995mm)

High-quality mobile experiment and demonstration trolley from the SybaPro range featuring aluminium table legs and low-level shelf.

This trolley is suitable for mounting under-table cabinets and is compatible with all add-ons and extensions in the SybaPro range.

It is supplied with one shelf, an angle bracket for attaching a PC and a cable holder.

Table top + Shelf:

- 30-mm table top made of highly compressed, multi-layer fine chipboard conforming to DIN EN 438-1

- Colour grey, RAL 7035, with 0.8-mm slightly textured laminate coating (Resopal) on both sides, conforming to DIN 16926

- Resistant to many chemicals and reagents including dilute acids and alkalis

- Resistant to heat, e.g. molten solder or heating at specific points such as by soldering tips or cigarette ends

- Frame with solid impact-resistant protective edging made of 3 mm thick RAL 7047 coloured plastic

- Coating and adhesive are PVC free

- Power strip with 6 outlet sockets mounted underneath the table top, lead and earthed plug

Frame:

- 2 extruded aluminium profiles with multiple grooves 1800 x 120 x 40 mm (WxHxD)

- 8 equally sized grooves in extruded aluminium profiles (3 on each side and 1 each on the front and back)

- Grooves accommodate standard industrial mountings

- 4 H-shaped aluminium profiles, 1150 mm, for 3-layer organisation of DIN A4 panels

- Space for extension of power supply duct

- Base made of rectangular tubing with 4 swiveling double casters, 2 of which have brakes

- Table frame made of tough combination of rectangular tubing around the full perimeter

- Acid-resistant epoxy-resin coating, 80 µm thick (approx.), colour RAL 7047

Cable holder:

- Width 200 mm with 12 cable slots to accommodate 48 x 4-mm safety measurement leads

PC attachment bracket:

- With 3 screw-on rubber stoppers, dimensions 65x65x114 mm approx. (top fixing for PC)

> The height of the cable holder and PC attachment bracket can be adjusted along the aluminium profiles

> For attachment to left or right, fastening materials included

> Acid-resistant epoxy-resin powder coating of thickness 80 µm approx., colour RAL 7047

Dimensions:

- Height of table top 760 mm

- 1250 x 1970 x 700 mm (WxHxD)

- The mobile experiment stand is supplied in kit form and needs to be assembled by customers themselves.

Monitor Holder for Flat Screen Monitor of Weight up to 15kg / 33lbs

Pivoting monitor holder for attachment to aluminium profiles of furniture in the SybaPro range. Allows a monitor to be placed in the optimum position so that work and experiments are less tiring.

- Pivoting arm with two-part joint

- Quick-lock for adjustment to any height on extruded aluminium profile

- VESA fastening 7.5 x 7.5cm

- Includes VESA 75 (7.5x7.5) - VESA 100 (10x10) adapter

- 2 Cable clips

- Adequate carrying capacity 15 kg / 33 lbs

- TFT monitor can be turned parallel to the table edge

- Separation can be adjusted to anywhere between 105 and 480 mm

Additionally included:

Cable management set for installing cables along the profiles of the aluminium lab system furniture in the SybaPro range, consisting of:

- 3 Cross cable blocks for front and rear grooves of aluminium profile

- 3 Cross cable blocks for side grooves of aluminium profile

- 12 Cable ties

- 4 Aluminium cover profiles for covering and enabling wires to be run along the grooves of an aluminium profile

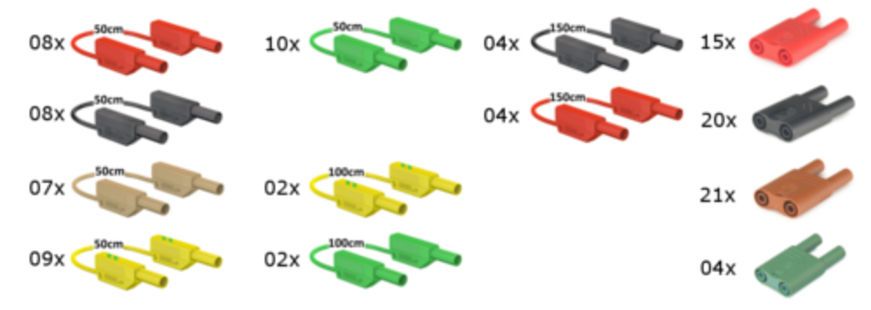

Set of Leads for "Modular Engine Management"

This set of 4-mm connecting leads has been specially assembled for the "Modular engine management: Common rail" training system, i.e. the actual colours and the lengths of the leads enhance the educational concept behind the training system itself. This makes it easier to distinguish between sensors, actuators and power supply. All the measurement leads and jumpers are special models which make it impossible to come into contact with any live electricity. To make measurements easy, all the jumpers have a single contact. In addition, the number of leads and jumpers provided is such that replacements are already available should any be lost. The content of the set in detail is as follows:

Jumpers

- 15 x Jumpers (red)

- 20 x Jumpers (black)

- 21 x Jumpers (brown)

- 04 x Jumpers (green)

Connecting leads

- 08 x Safety measuring leads (red, 50cm)

- 07 x Safety measuring leads (brown, 50cm)

- 08 x Safety measuring leads (black, 50cm)

- 10 x Safety measuring leads (green, 50cm)

- 09 x Safety measuring leads (yellow, 50cm)

- 02 x Safety measuring leads (green, 100cm)

- 02 x Safety measuring leads (yellow, 100cm)

Measuring leads

- 04 x Safety measuring leads (red, 150cm)

- 04 x Safety measuring leads (black, 150cm)