CarTrain Direct Fuel Injection

Part No.: MPLCNL-CarTrain-Direct-Fuel-Injection

The training system is designed to perform actuator control as a function of corresponding sensor signals.

產品介紹

CarTrain Direct Fuel Injection

The MED direct fuel injection system with turbo charger combines the entire engine control system (air-fuel mixture and ignition) in one single control unit. The MED direct fuel injection with turbo charger is a multi-point injection system meaning that each cylinder is equipped with its own injection valve. The training system is designed to perform actuator control as a function of corresponding sensor signals. Different driving conditions can be reproduced and understood. The sensors and actuators used in the engine management system are original, fully-operational components.

List of Articles

CarTrain MED Gasoline Direct Injection System with Turbocharger

The CarTrain MED gasoline direct injection system with turbocharger offers users an effective and efficient learning environment on the topics of automotive technology utilising a wide variety of media. It is based on the latest technology and educational experience, utilising all today's technical possibilities. The interaction between various media in the learning environment gives trainees a comprehensive view of the engine management system, leading to genuine and recondite understanding.

The system combines hardware and software in a way that makes perfect educational sense. The experiment hardware involves authentic vehicle components. Each module is viewed in realistic fashion as an individual component and as part of the engine management system. Components are connected to a control unit, which picks up the signals from the connected sensors and operates the actuators accordingly. This means it is possible to see the interactions in an input-processing-output principle as used in practice.

The accompanying software contains the complete course and provides multimedia representations of all the hardware components. Its contents cover the full system, its open and closed loop control circuits as well as the individual sensors and actuators. Trainees are continuously encouraged to work interactively. Numerous instructions for experiments and component measurements are included.

Full wiring ensures that the training system is quickly ready for use.

The CarTrain MED gasoline direct injection system with turbocharger features just one control unit, which encompasses the entire electronics for engine control (fuel management and ignition). The MED gasoline direct injection system with turbocharger is a multi-point injection system, in which every cylinder has its own injection valve. The training system implements the control of actuators depending on the relevant sensor signals. A variety of driving conditions can be simulated. The sensors and actuators are authentic components and are fully functional.

Training contents:

- How an engine management system works

- How the accompanying control systems work

- Design and function of sensors and actuators

- Interpretation and use of circuit diagrams

- Enhancing diagnostic skills

- Making measurements on the components of the engine management system as done in practice

- Use of standard diagnostic routines

- Limiting of faults and interference

- Function monitoring

- Sensory perception

- Fault memory read out

- Measurement and testing of electrical, electronic, hydraulic, mechanical and pneumatic variables

- Configuration of engine management systems

- Technical communication

- Drafting test reports, evaluating and documenting results

- Information flow between data transmission systems

- Expert systems and diagnostic telemetry

- Use of hotlines

- Programming control units via Ethernet

- Resets and basic configuration of control units

The training system includes the following:

- Hardware made by various vehicle manufacturers

- Hardware and software for theory and practical lessons

- Software for self-learning

- Pre-defined tests and test objects

- Computer-based theory with 3D animations

- Computer-based measurements in authentic experiments

- Functional OBD interface

- Connection of all typical testers used in garages and repair shops via diagnostic CAN

- Switch-over between actual and simulated operation of sensors

- PC-based fault simulation switches for 50 faults

The system contains a programmable control unit which can universally support any number of parameter sets by uploading software configurations.

- Operating voltage

- Air intake temperature

- Engine temperature

- Crankshaft speed

- Throttle position

- Lambda values

- Air intake volume

- Camshaft signals

- Anti-knock control

- Single spark ignition coils

- Idle setting

- Fuel pump control

- Tank bleeding valve

- Interface for multimedia experiment literature – measurements need to be copied into the experiment instruction pages using drag and drop.

- Two voltage values and one current can all be measured simultaneously

- 3-channel oscilloscope function can be used at the same time as the multimeter display

- Measurement range: V<250 V=/~, I<15A=/~ direct measurement within the circuit

- Current measuring range protected by automatic circuit breaker

- USB interface

Electrical connections are made via 4-mm safety sockets. They are logically labelled with the pin assignments. All sockets for measurements are 4-mm safety sockets and support the educational purpose in that sensor signals, actuator control and power supply sockets are all coded in different colours. This is a compact training system. ´The housing is made of highly rigid metal. Front and rear panels are 5-mm thick laminated compression mouldings coated on both sides with hard-wearing melamine resin coatings with a basic colour of RAL7035 (light grey). The equipment is approximately 800 mm high and 1000 mm wide. Photo-realistic colour printing is used on the front plate to represent the engine block and systems components in high-contrast UV colour, which does not fade even in bright sunlight. A special process involving an additional varnish firstly ensures that the equipment is robust and resistance to scratches without detracting from the clarity and comprehensibility of the front panel printing. The rear is connected from contact by a cover plate. The housing can be fitted into a special mobile experiment stand or it can be attached directly to a bench via safety feet.

Includes:

- Training system with 230-V, 50-Hz mains connection and integrated hardware

- 12-14-V power supply in the housing itself

- Set of measuring leads

- OBD diagnostic equipment

- USB cables

- CD with basic software

- Instruction manual

System requirements:

- Personal computer with Windows Vista, Windows 7 (32- or 64-bit version)

- CD-ROM drive for installing software

- USB port for connection to measurement hardware

Technical data:

- Dimensions: 100,2 x 22,1 x 80,4 cm (WxHxD)

- Weight: 40 kg

Additionally Required

Over-/Under Pressure Pump

Manual pump for monitoring and setting under-pressure or over-pressure functions. Quick and easy to use. Integrated discharge valve for reducing the under-pressure or over-pressure, without removing the terminal connections. With a connection hose and a variety of end pieces.

- Under-pressure: -1000....+1000mbar

- Weight: 0.4kg

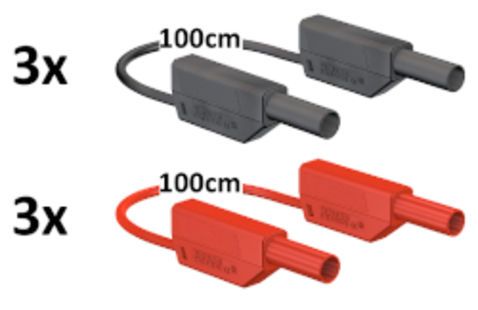

Set of Leads for CarTrain Engine Management Training Systems

This set provides you with the 4-mm safety leads you need to carry out the multitude of experiments possible with the CarTrain training systems. The leads are simply connected by means of 4-mm safety sockets to the measurement unit and the components upon which measurements are to be made.

The set of leads contains:

- 3 x 4-mm safety measurement leads, red (100 cm)

- 3 x 4-mm safety measurement leads, black (100 cm)

Additionally Recommended

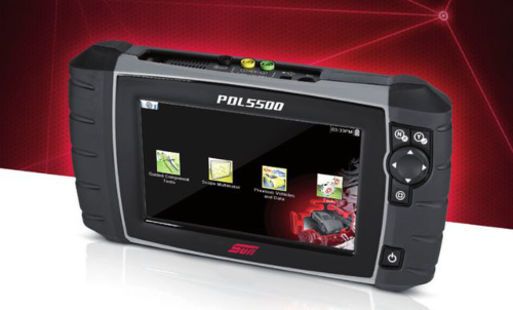

Sun Handheld Diagnostics Unit PDL 5500 German Version

SUN PDL 5500 – Official successor to the world renowned "MODIS" diagnostic tester

Customer satisfaction and the success of the earlier MODIS were motivation enough to make the best even better. That is why all the existing functions have been redesigned, made simpler and further optimised. There is more functionality, a faster operating system and a bigger 8“ colour touch screen. That means that the PDL 5500 has not merely been restyled but completely reconceived.

The inexpensive SUN PDL 5500 multi-function equipment is an unusual combination of tried and trusted technology with ease of use, tailored to the everyday needs of modern vehicle repair shops. The SUN PDL 5500 only needs 5 seconds to boot and displays fault codes and live data within 30 seconds. A guided Fast-Track® component test for easy location of faults is also built in. Rapid comparison between component faults ensures certainty and clarity in seeking out faults.

Key features:

- Scanner, oscilloscope and expert information in a single device

- Navigation by means of intuitive 8" touch screen or 4-key key-pad

- Measurement data can be stored on a MicroSD card

- Communication with a PC via USB and ShopStream software

- Graphic, digital, 2-channel multimeter

- 2-channel high-speed trigger and lab scope

- Guided component tests

- Manufacturer-specific model coverage for more than 40 marques

- Coverage for multiple vehicle systems (TPMS, PDC, suspension, hybrid drives etc.)

- Provides manufacturer-specific codes, live data, function tests plus learning and adaptation functions.

- Rechargeable battery charged via OBD terminal

- Dimensions: 285 x 50 x 150 mm/Weight: 1.2 kg

Protection Cover for CarTrain/InsTrain Experiment Trolleys

.jpg)

Dust cover for CarTrain/InsTrain experiment trolleys

- For protecting equipment from dust and damp

- For keeping equipment out of sight

- Colour: matt dark grey with printed LN logo in orange)

- Material: nylon fabric with polyurethane coating

- High resistant to tearing, impregnated to be washable and waterproof

Accessories

Set of Circuit Breakers for Vehicles (10A/15A)

.jpg)

- Single-pole thermal circuit breaker for vehicles, slim format with coloured manual trip switch

- Reliable tripping response thanks to snap-action trip switch

- Tamper-proof rip interlock to prevent reactivation of the circuit till the fault is rectified

- Plugs into low-profile vehicle fuse box

- Nominal voltage 12V

The set comprises the following components:

- 1x 10A vehicle circuit breaker

- 1x 15A vehicle circuit breaker

SybaPro Mobile InsTrain/CarTrain Experiment Trolley, 1070x1350x700mm

The mobile aluminium-profile experiment trolley is specially designed to accommodate components of the InsTrain and CarTrain system. All the Ins-Train and CarTrain system components can be safely mounted in structured fashion for lessons from the front of a class or for students' own practicals. For students, this provides a modern, educationally designed workplace with a worktop and connections for multimedia.

- The mobile experiment stand is delivered in kit form and needs to be assembled by the customer

- Aluminium profile with integrated grooves for attaching a wide variety of components (e.g. PC and monitor-holders)

- 4 steerable double casters, 2 with brakes

- Worktop 1000 x 30 x 700 mm (WxHxD)

- Table top made of highly compressed multilayered chipboard conforming to DIN EN 438-1, light grey, with double-sided 0.8 mm slightly textured laminate coating (Resopal) in compliance with DIN 16926

- Table top bordered with solid, impact-resistant edging made of 3-mm thick plastic, colour RAL 7047

- Coating and adhesives must be PVC-free

- Power strip with 5-outlet sockets and power switch, lead and earthed plug

- Height of table top 830 mm

- Dimensions without CarTrain/InsTrain-System: 1070 x 1350 x 700 (WxHxD)

- Dimensions with CarTrain/InsTrain-System: 1070 x 1650 x 700 (WxHxD)

Monitor Folder for Flat Screen Monitor of Weight up to 15kg / 33lbs

Pivoting monitor holder for attachment to aluminium profiles of furniture in the SybaPro range. Allows a monitor to be placed in the optimum position so that work and experiments are less tiring.

- Pivoting arm with two-part joint

- Quick-lock for adjustment to any height on extruded aluminium profile

- VESA fastening 7.5 x 7.5cm

- Includes VESA 75 (7.5x7.5) - VESA 100 (10x10) adapter

- 2 Cable clips

- Adequate carrying capacity 15 kg / 33 lbs

- TFT monitor can be turned parallel to the table edge

- Separation can be adjusted to anywhere between 105 and 480 mm

Additionally included:

Cable management set for installing cables along the profiles of the aluminium lab system furniture in the SybaPro range, consisting of:

- 3 Cross cable blocks for front and rear grooves of aluminium profile

- 3 Cross cable blocks for side grooves of aluminium profile

- 12 Cable ties

- 4 Aluminium cover profiles for covering and enabling wires to be run along the grooves of an aluminium profile

PC Holder for SybaPro Experiment Trolleys, Height/Width Adjustable

Shelf for desktop PC made of 2 mm sheet steel punched with holes, suitable for all furniture in the SybaPro aluminium profile range

- Adjustable assembly height

- for slim PCs, adjustable width (60 - 160 mm)

- with fastening and rubber stopper

- Can be mounted to left or right

- Includes all equipment necessary for assembly (4 bolts and 4 tenon blocks)

- Acid-resistant epoxy-resin powder coating, 80 µm thick approx., colour RAL7047

Under-Table Cabinet, Suspended, 4 Drawers, Central Locking

- 1 Utensil drawer

- 1 Drawer, 2 HU

- 2 Drawers, 4 HU

- Usable width: 330mm, usable depth: 480 mm

- Central locking

- Metal drawers with surrounding row of slots

- Body made of 19 mm-thick, highly-compressed, multi-layered fine chipboard with grade E1 plastic coating on both sides

- Dimensions: 430 x 580 x 590 mm (WxDxH)